Powering Earthquake and Volcano Monitoring

LE-v50 Extreme & LE-v150 Extreme surviving in winds up to 85mph

The Leading Edge LE-v50 Extreme vertical axis wind turbine is a compact, silent and lightweight turbine designed for battery-charging of low power electronic devices (not for domestic use).

These include data-loggers, radio and telemetry equipment in some of the world's harshest locations - Antartica, Greenland and Arctic Canada. The vertical axis design is able to work effectively in challenging conditions compared with a horizontal axis turbine, read this article in Energy Engineering magazine.

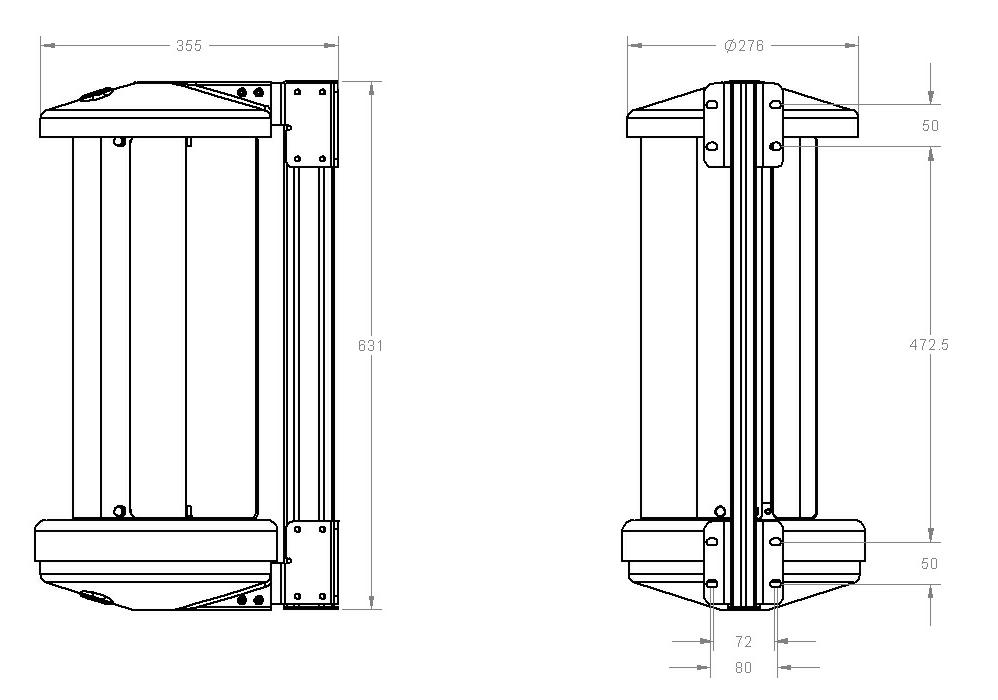

The LE-v50 Extreme is available as a 12V, 24V and 48V wind turbine. Included 4 x 70mm U-bolts (BZP) for side mounting to 50mm or 60mm OD pole.

Where wind gusts to 35m/s (80mph) or temperatures drop down to -40degC, the LE-v50 Extreme turbine is the wind turbine of choice. It features enhancements that reduce the stress and fatigue on the blades during prolonged periods of storm force winds.

Features include aluminium blades, polycarbonate cowlings, blade load spreader plates, an upper baffle plate to prevent damage to the upper cowling and the black body to reduce the build-up of rime ice.

Aluminium blades, proven Savonius rotor design and build quality enables it to survive winds up to 35m/s (80mph)

With only one moving set of parts and no brushes to wear out

Easy to install in places where space is a premium

At only 9kg, the LE-v50 Extreme wind turbine can be installed with ease

Low temperatures bearings and polycarbonate materials ideal for temperatures at -40degC

Designed for corrosive marine environment

The LE-v50 Extreme uses a proven ‘Savonious’ rotor design which gives silent and effective performance. Using the latest solid modelling and Computational Fluid Dynamic simulations, we have come up with an elegant ‘cross-ventilated’ rotor which provides good power conversion for a vertical axis wind turbine of this size.

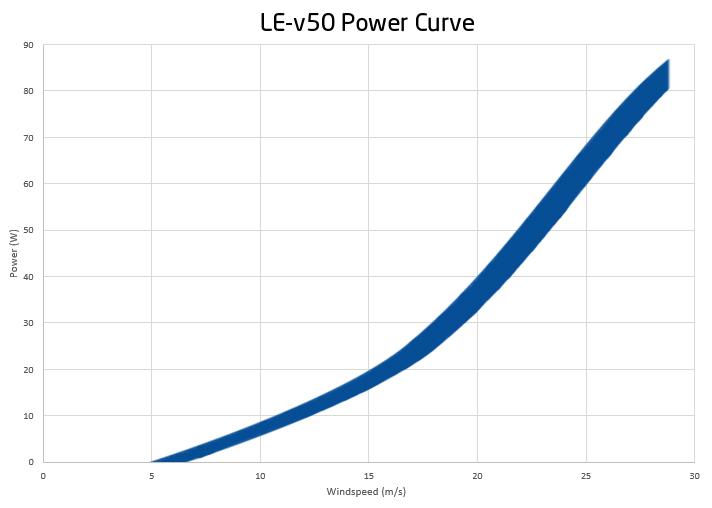

This wind turbine will output 10 watts @ 12m/s (26mph) with a peak output of 70 watts according to the power curve if sited correctly - read our siting advisory document.

The rotor is then coupled to our specially designed low inertia, zero ‘cogging’ axial flux permanent magnet alternator. Using Neodymium rare earth magnets, this alternator design has become one of the most field proven and effective alternators that is deployed across the entire range of Leading Edge wind turbines!

Unlike any other small wind turbine you will find, this turbine can even be allowed to run ‘off-load’ with no connection to the batteries. The LE-v50 Extreme’s rotor design will limit its RPM automatically. If anything comes into contact with the rotating blades, it will be pushed away from the rotor rather than being caught by the spinning and causing damage.

These safety features make the wind turbine ideal for installation in places where space might be an issue, and where people are nearby.

The LE-v50 Extreme wind turbine is manufactured from high quality aluminium alloys which have been laser processed, CNC machined, hard anodized and powder coated to ensure that the turbine will withstand the harsh effects of the extreme environments that it was originally designed for.

With only 1 moving part, there is little to go wrong and no brushes or slip-rings to wear out and need replacing. The bearings are sealed for life and fully lubricated, so no greasing or maintenance is required. All of the fixings are manufactured from A4 stainless steel which are able to withstand the most corrosive of environments.

Our Off-grid experts will come back with recommendations

Stay up to date with Leading Edge innovations and offers by joining our mailing list. Occassionally we send informative newsletters, offers and promotions that we think you'll find useful or interesting.